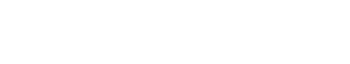

OUR LEADING PRODUCT

KEY TECHNOLOGY OF RECYCLING SYSTEM

PLASTIC CRUSHER

RECYCLE PELLETIZING MACHINE

PLASTIC WASHING LINE

Who We Are

SIMPLE RECYCLING SOLUTION

ONE-STEP PROCESS

KITECH is a global active machinery corporation, specialized in developing plastics recycling machines and system components, devoted to creating our equipment with a high level of innovation, durability and operational reliability.

25+

Over 25 years of knowledge

25+

Over 25 years of knowledge

and experience in plastic

recycling and

extrusion filed

200+

More than 200 plastic

200+

More than 200 plasticrecycling projects installed

successfully

50+

Satisfied more than 200

50+

Satisfied more than 200

customers in 50 countries

and regions

6+

Agents on more than six continents

6+

Agents on more than six continents

Products

Extraordinary Recycling Equipment Manufacturer

Our Projects

Recycling System for Regrind HDPE/PP Flakes

Nigeria

Nigeria

The plastic recycling solution designed specifically for the Nigerian market. It can efficiently processes HDPE/PP rigid mixed materials,eliminating waste at customer’s facility.

The resulting pellets will be directly sold to injection molding factories, helping customer maximize profits. This innovative approach not only reduces material loss but also creates a sustainable revenue stream.

PE Film Recycling Machine with Laser Filter

UK

UK

This is a highly efficient granulation production line designed specifically for recycling PE film. Equipped with advanced 5G laser filter technology, it effectively filters impurities in plastics, ensuring high-quality output at a rate of up to 600kg per hour.

This solution offers excellent performance and reliability for clients seeking stable, large-scale plastic recycling.

Single Stage Pelletizing System for HDPE Pipe Flakes

Iran

Iran

This reliable plastic recycling granulation line, recently designed for the Iranian market. This system features a single-screw extruder equipped with a plate screen changer, delivering an efficient output of 1000-1200 kg/h.

Ideally suited for processing HDPE pipe materials, this solution enables smooth reprocessing into high-quality pellets for resale.

KSP100 Single Screw Under Water Pelletizing System

NZ

NZ

The KSP100 single-screw pelletizing line, designed to deliver exceptional efficiency and reliability. Equipped with a laser filter device, it significantly reduces labor and downtime. With a capacity of 350kg/h, this system is ideal for processing hard PP materials with speed and precision.

KLF365 Laser Filter-automatic and Self-cleaning Screen Changer

Chile

Chile

The Laser Filtration Screen Changer, successfully delivered to Chile for integration into a plastic recycling pelletizing line.

This system effectively filters impurities from raw materials, ensuring cleaner particle output. Its automatic cleaning scraper significantly reduces manual labor costs associated with screen changes.

Double Stage Pelletizing Machine for Recycling PP Regrind Flakes

Russia

Russia

This is a double-stage single screw plastic recycling pelletizing line, designed for efficient processing of washed PP/PE flake materials. Featuring laser filter and plate type filter, this production line delivers stable performance with a capacity of around 400kg/h. The resulting pellets are widely used in injection molding applications, making this system an ideal choice for high-quality plastic recycling.

News & Blog

Read Our Latest News

Blog & Articles

5G KCP160 Compacting Pelletizing System Successfully Installed in Canada

In a significant advancement for the plastic recycling industry, our company has successfully installed the new 5G KCP160 Compacting Pelletizing System at a customer’s factory in Canada.

KITECH’s Anniversary Celebration

KITECH’s Anniversary Celebration On September 30th, KITECH MACHINERY proudly celebrated its anniversary, marking a significant milestone in the company’s journey. The event was

KITECH participated in American and Saudi exhibitions achieved great success

KITECH, a leading company in the production of plastic recycling machines, has recently achieved great success at the American and Saudi exhibitions.

KITECH MACHINERY

OUR EVENTS